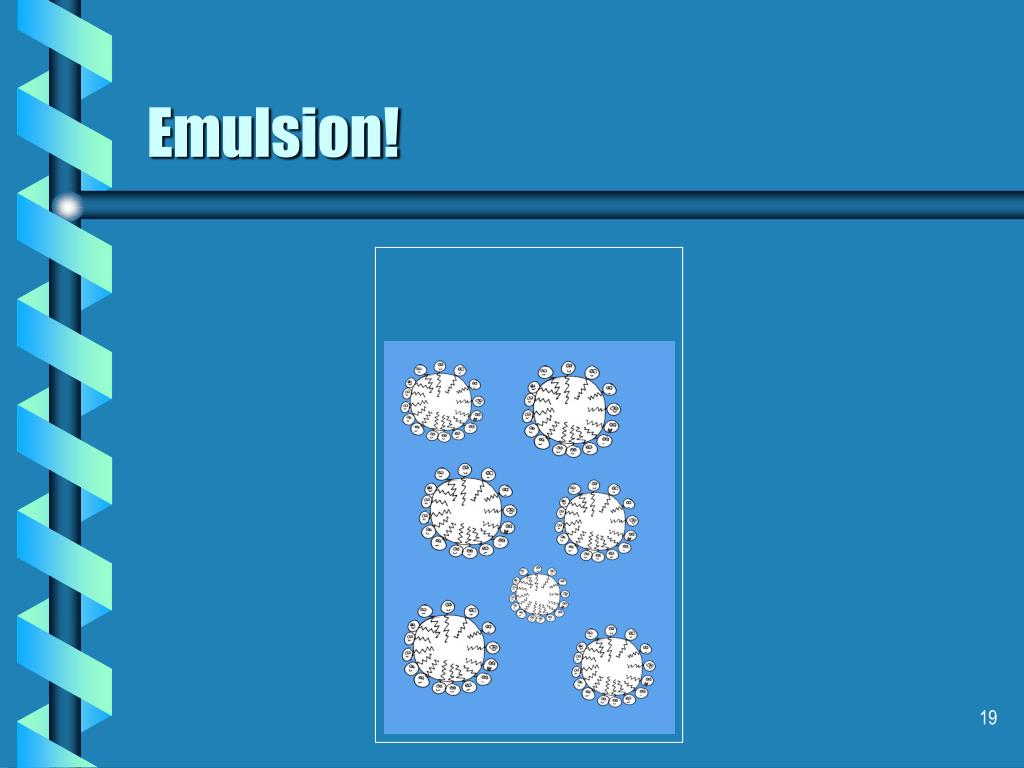

Typically, this is a surfactant used for the sake of forming the emulsion. The traditional emulsification methodĭuring the process of emulsification, an emulsifier must be employed. Thus, it is always a challenge to obtain a practically stable emulsion on a large scale with minimised cost. They want to be separated and achieve this equilibrium. However, if the emulsion is at a nonequilibrium state, there is pressure on the two phases to separate: oil does not want to hang out with water and water is not fond of oil. In addition, utilising the nonequilibrium state of the emulsion can create sophisticated tactile sensations which are one of the important properties of these products.

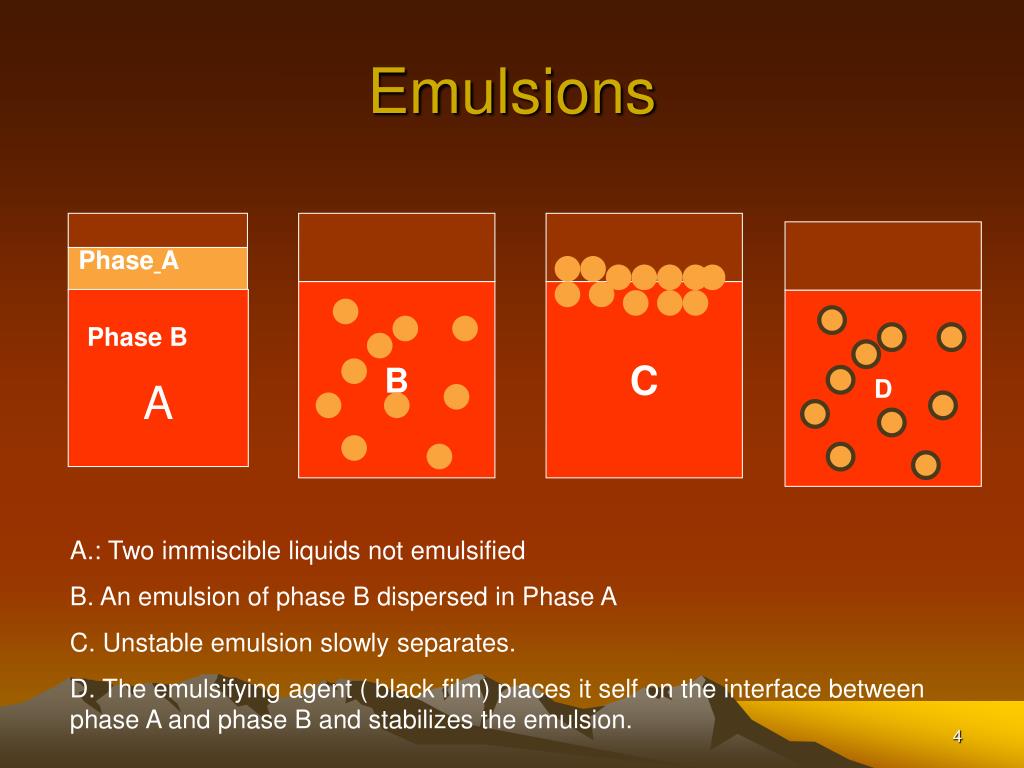

The two main functions of products created from emulsion are those that are used to moisturise, nourish and protect the skin, and those used to deliver active ingredients or other components. In cosmetics and personal care, emulsions allow formulators to create a lotion or cream that contains both an oil and a water phase, combining lipid-based emollients with the moisturising components of a formulation. A number of emulsion systems are found in nature and our bodies bile acid acts as an emulsifier to help digestion and absorption of fat by the formation of finely dispersed emulsion droplets, and lipoprotein forms an emulsion to deliver and metabolise fat in the body. Emulsification is the “process” of making a metastable mixture of two such immiscible materials, like water and oil, which under normal conditions eventually separate into two phases in equilibrium.Ī prime example is mayonnaise, which is an emulsion of water-based materials, with oil that is blended into a semi-solid emulsion form. In general, emulsions are dispersions of two (or more) immiscible liquids.

Many products, including foods, drugs, and personal care products are emulsion-based. These products can reduce time and costs, help mitigate unnecessary complexity and are highly scalable. In comparison, more optimised products have evolved featuring new technologies, such as emulsion concentrates like HydraMaxx. However, with complexity around using emulsifiers, supplemental products to ensure stability and, among other factors, the need for heating, homogenization and cooling, the traditional production process remains ineffective, costly and environmentally unfriendly. The benefits of Using Emulsion Concentrates: BioAktive HydraMaxxĮmulsions play an essential role in the production of lotions and creams in the cosmetics industry.

0 kommentar(er)

0 kommentar(er)